Stainless steel hose is a type of equipment widely used in civil and industrial piping systems. Today, E-Flex Vietnam will learn with you how stainless steel hoses are manufactured.

Main contents:

In this article, we basically refer to the production process of flexible pipes (also known as stainless steel pipes, stainless steel anti-vibration pipes, bellow, ..) made of stainless steel (not included). braiding layer). This is a type of pipe that requires high-precision manufacturing technology and careful calculation to meet specific functional requirements.

How Are Stainless Steel Hoses Made?

In order to produce stainless steel hoses with sine waves, making the pipes elastic and flexible, we need professional production lines in factories.

Stage 1: Create stainless steel pipe.

Raw stainless steel material (Inox 321 or Inox 316L) will be processed and put into line to form hard tubes. Rigid pipe will have size, thickness depending on its molds.

Immediately after, the inspection steps will ensure the tube is completely sealed before moving on to stage 2.

Stage 2: Create corrugations on the tube.

After having stainless steel pipes, the technician will transfer them to the mechanical chain to create corrugations on the pipe.

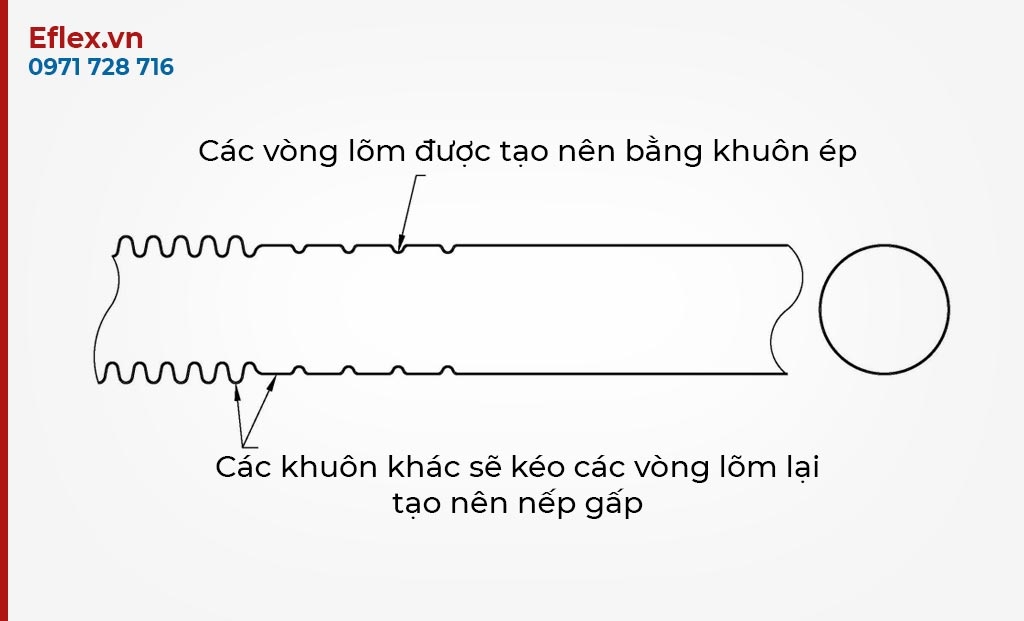

The first step: When the tube is put into the corrugated machine, the clamping dies of the machine will hug the tube body, the force of pressing the mold against the tube body will create concave rings. This step will create a series of concave rings with equal spacing.

The figure depicts how stainless steel hoses are made with 2 basic steps.

Next step : In this step, other metal molds are used. This mold will be pressed into the correct position of the concave rings, every 2 molds after tightening will be pulled closer together thereby creating a fold, many folds will create a sine wave. This step will create sine waves thanks to the concave rings from the first step.

Each tube size will have waves with different wavelengths.

With larger sized pipes, the corrugation technique will require more technique. Depending on the factory, phase 2 may have some other specially developed wave-making technologies such as: hydraulic press from inside, etc., etc.

Finally, the pipes will be tested to ensure tightness, ensure the technical requirements for pressure resistance, etc. before finishing.

Above, we have mentioned the basic steps to create the finished product, which will actually include other more complex stages. At E-Flex Vietnam , stainless steel hoses will be carefully selected from reputable suppliers to ensure finished products: stainless steel anti-vibration pipes , stainless steel flexible joints of the highest quality.